BOX PACKSLIP

Pack slip is a feature which enables a user to create multiple boxes dynamically and generate box specific packing slips in Uniware for the shipments while scanning items for invoicing. These pack slips help the user to identify the package contents and automate pack slip generation in the warehouse.

System Specifications Required- Supported for both ITEM & SKU level traceabilities. Pack slip configuration can be enabled on channel connected to each tenant.

Applicability

Version: Professional and Enterprise

Traceability: SKU, ITEM

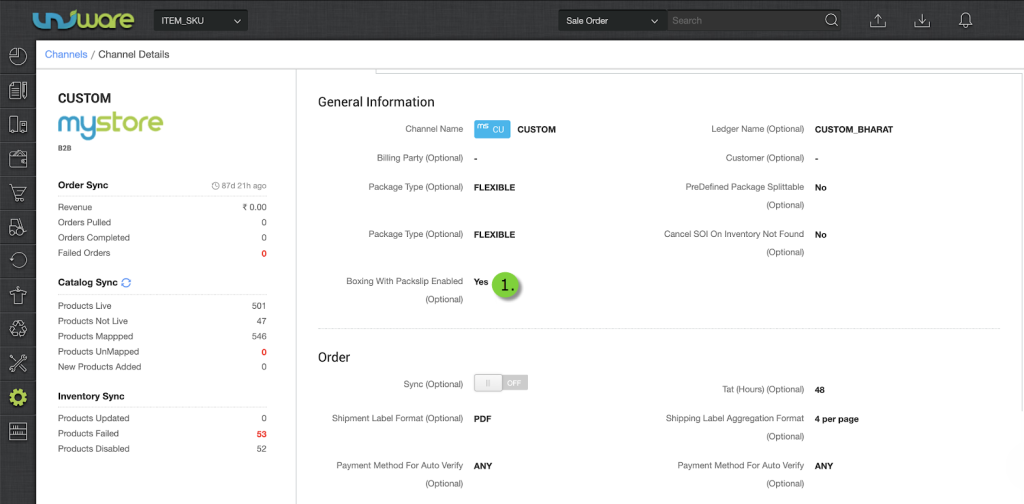

Channel Setting Configuration:”Boxing With Packslip Enabled” = Yes

Box Pack slip Process Overview-

– Uniware will automatically assign an ‘open’ box as soon as the first item is scanned.

– User can scan & pack more items in that box and once box has sufficient items, user can ‘close and assign new boxes successively to scan and pack balance items.

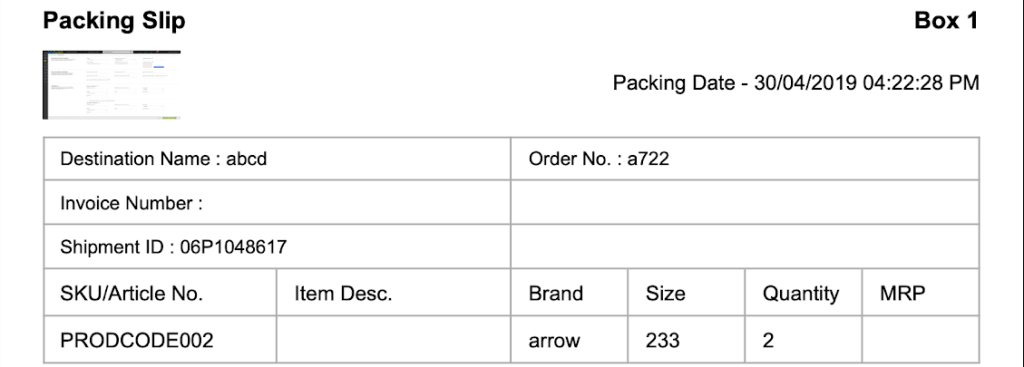

– On the closure of each box, the system will automatically print a pack slip for that box and scanning can continue further.

– After all the items are scanned and the last box is closed, the system will automatically print a final invoice and pack slip for the last closed box.

– User can reprint pack slips later for all boxes belonging to a particular shipment.

How to create Pack slips in Uniware?

Follow the simple steps to create Box pack slips in the system:

1- Go to Settings> Channels > Custom channel (Click here to know what is a Custom channel and why do we need it?)

Thereafter, Enable the parameter “Boxing With Packslip Enabled” at the custom channel page which is NO by default.

*Note- This feature is available to process B2B orders created manually/via import in Uniware. To know how to create orders in the system, please refer to link here.

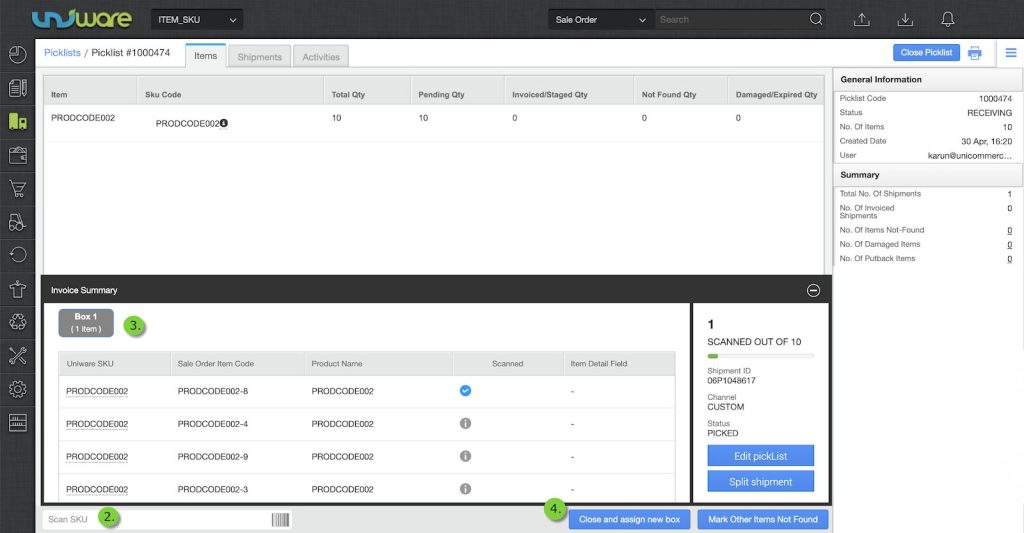

2- Once we have an order in the system and start processing it via picklist, the system automatically assigns a box just after the 1st item is scanned

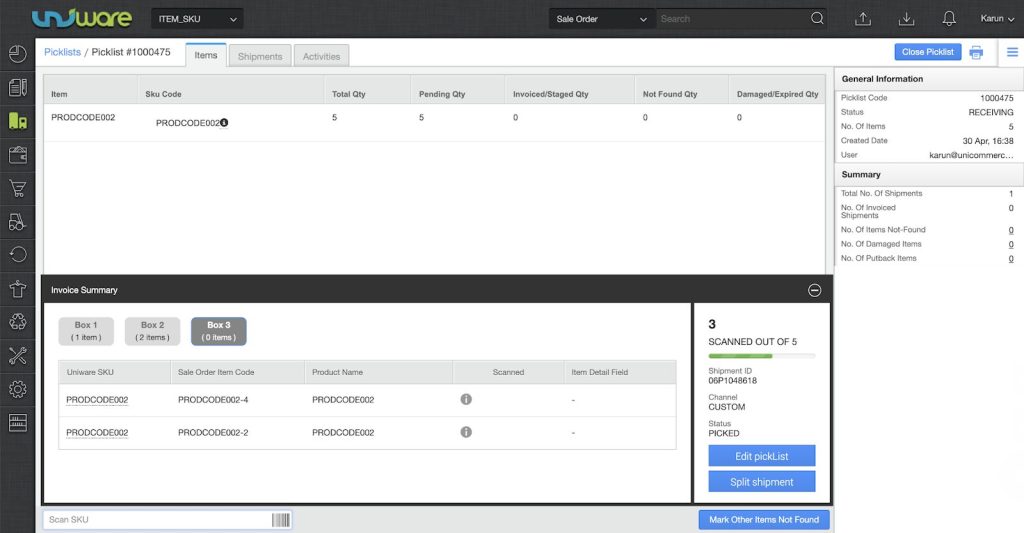

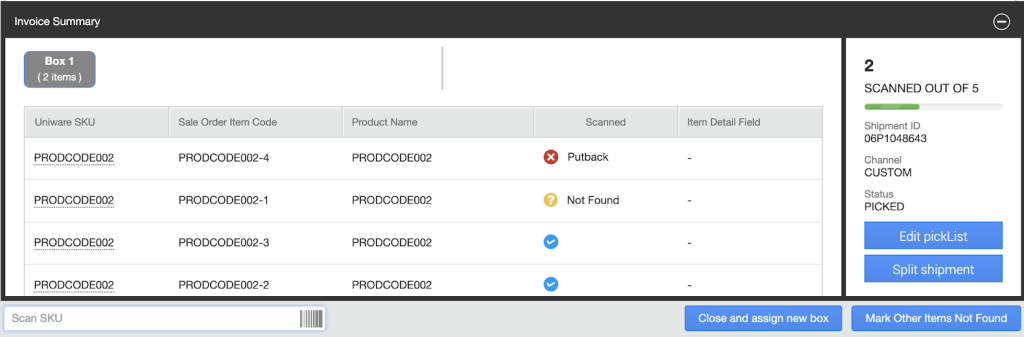

3- During scanning multiple boxes can be assigned to a particular shipment

4- Once each box is closed system redirects the user to the pack slip of that box

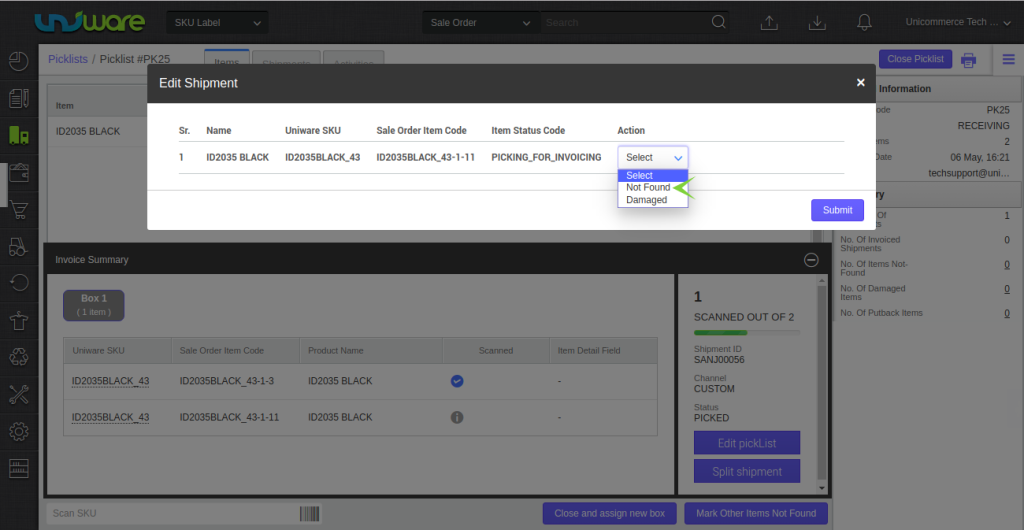

**Note: If the order item to be scanned is Damaged/Not Found user can mark same while scanning the picklist using![]() button.

button.

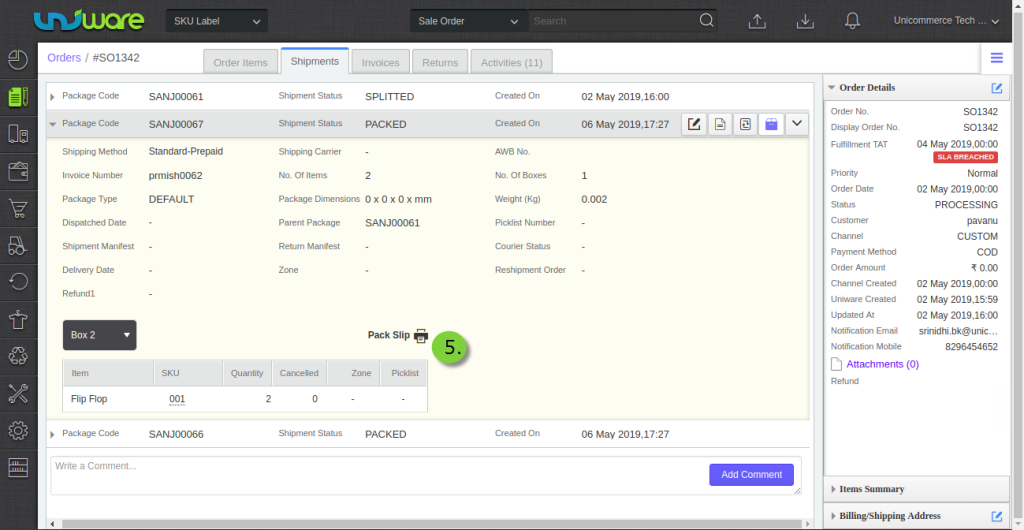

5. After the last box is closed system automatically prints the shipment invoice and pack slip for the last box closed. Once the scanning is over user can see box details and print each pack slip again on the shipments page, if required.

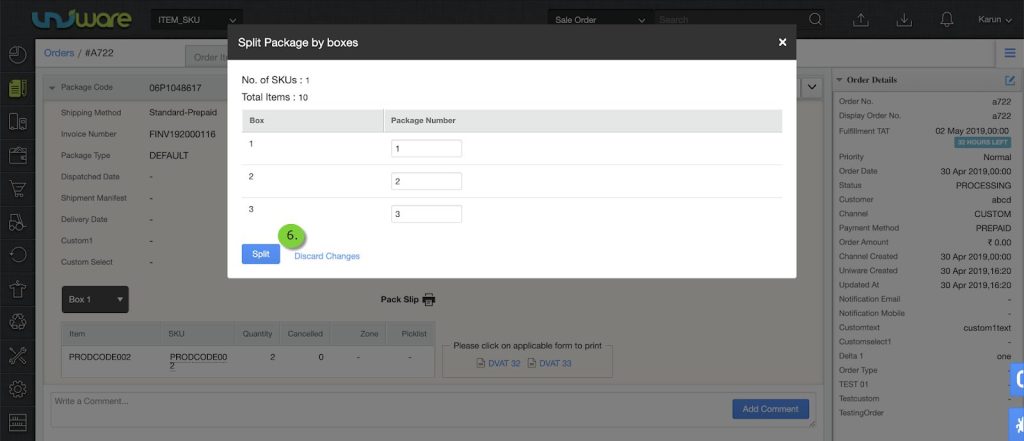

6. User can also split a PACKED shipment containing multiple boxes into multiple sub-shipments

Note:

- We provide support handheld for Box Packslips and Box Code to get streamline operational flow.

- How to create package type Click Here

PR-1189 1866203137