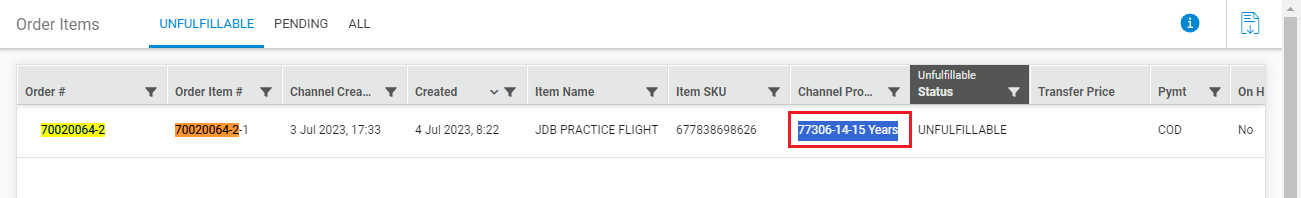

We know that an unfulfillable order item means that the system inventory for such an item is “zero”. We must realize that there are various reasons why the inventory of an item can be “zero”, these are listed as below:

Always Remember: If you have physical stock of any item, keep it updated on the system by either manually adding the values on Inventory page or uploading the latest numbers on bulk imports.

A:-Inventory of an item was just 0, but multiple orders receives in Uniware from the same item SKU.

Action: Please connect with the Channel representative, as this case will be handled by channel team to share the RCA for the last inventory received from Uniware side.

In this case, compare the TimeStamp for order creation with last Inventory synced from UC.

For example:

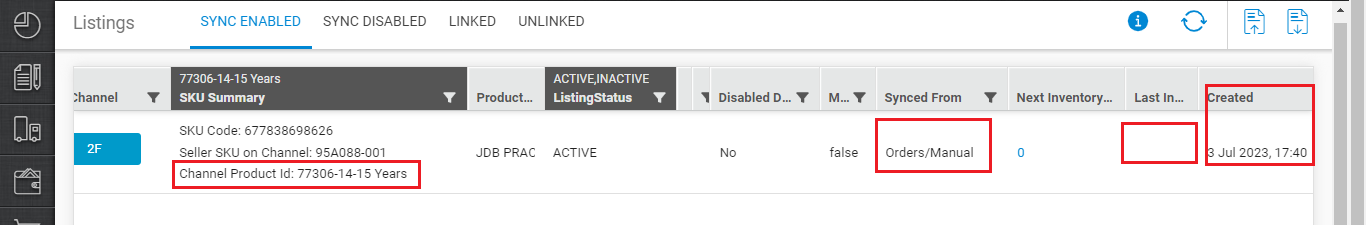

For the listing id “77306-14-15 Years” channel received the order at 3 Jul 2023, 17:33 and listing was created at 3 Jul 2023, 17:40

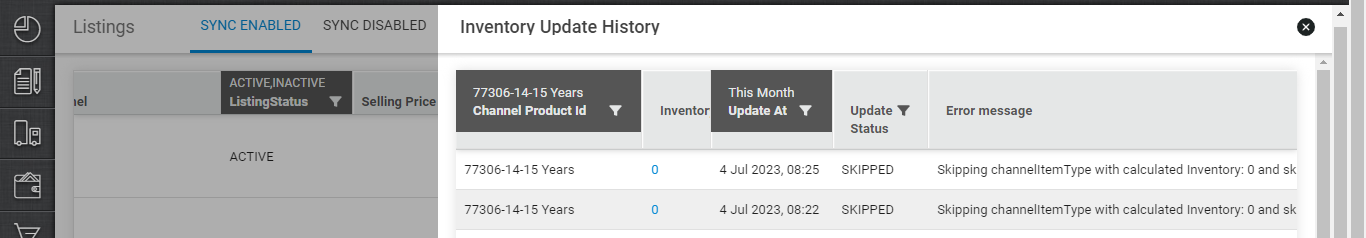

Check the inventory history for the correct listing id ” 77306-14-15 Years” and check the last inventory synced from UC to channel.

The last inventory from UC was not successfully update due to the mentioned reason of mapping via manual instead of catalog.

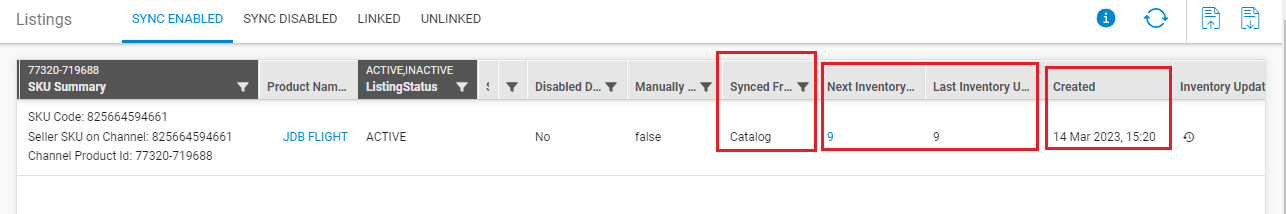

Note: In standard case order must be created on channel after the inventory get synced from UC as below shown:

Always Remember: Uniware only push the inventory for such listings for that stock is updated via uniware. Sellers should avoid the stock changes at the channel backend; otherwise, Uniware will not update the next inventory under redundancy.

B:- The item inventory is available on the channel (marketplace/website) but it is not updated in Uniware

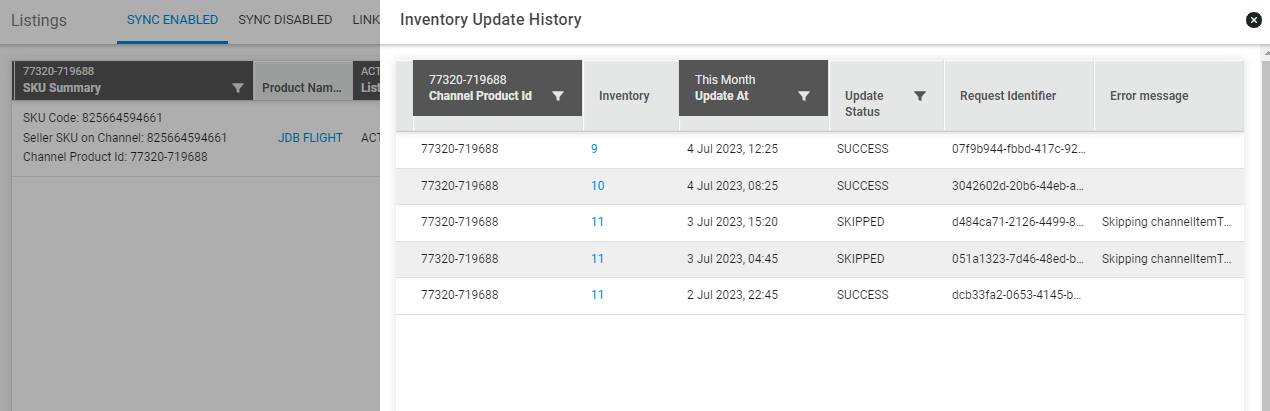

Action: Filter out the particular SKUs or Channel Listing Id on the Listings page and then check its inventory update history.

If the last sync is more than 10 minutes ago, then trigger the inventory sync again.

Please note: In case of a failed attempt, the page also highlights the Error Message.

- Check the updated inventory count again.

- In case, it still doesn’t reflect the correct count, check with our support team.

C:- Product is created and mapped in Uniware but its inventory has not been synced/updated yet.

Action: Check the Inventory Adjustment History on the Inventory page.

Now filter the required SKU code to check the last inventory adjustment made against it.

If you find any discrepancy here, manually trigger the inventory sync for the channel again.

D:- The Inventory Sync for a channel is not activated, but Uniware receives an order for that channel.

Action: Please call the Channel representative, as this case will be manually handled by them.

E:- Inventory of an item was just 1, but multiple orders came in from different channels for the same item.

Action: In such a case, the first order item will be allocated, while the rest of them will go unfulfillable. Please understand that this situation can be avoided if you apply Buffer Inventory formula for various Order items.

To know more about it, please contact our Customer Care.