Batching in a general sense is a method of grouping SKUs based on pre-defined parameters. In Uniware, the SKUs can be batched together based on the various parameters, which need to be defined while creating a batch group in Uniware.

Applicability

Version: Enterprise clients Only

Traceability: SKU trace (Batching Traceability)

Configuration: General setting ‘Batching Enabled’ must be set to True for a facility or a tenant (all facilities). and all related config for respective batching flow (if needed)

What is a batch ?

A batch can be a container of 100 Pepsi bottles or 100 tomatoes or 100 milk packets.

Like:

Batch 1 : 100 Pepsi bottles (Mfg: 1st Jan, Exp: 1st Feb, Vendor: abc)

Batch 2 : 100 Pepsi bottles (Mfg: 1st Mar, Exp: 1st Apr, Vendor: abc)

Batch 3 : 100 Pepsi bottles (Mfg: 1st Jan, Exp: 1st Feb, Vendor: xyz)

Why batching ?

- A middle path between SKU & ITEM traceability.

- Better inventory tracking using attributes (MRP, Vendor Name, Cost, Mfg. Date, Expiry Date, Country of Origin, Bill of Entry and Vendor Batch Number.).

- Identifying production line/vendor sourcing related errors.

- Identify and sell soon-to-expire inventory on multiple marketplaces or liquidate them whenever required

- Achieve minimal expiry and spoilage, effective space utilization and better inventory procurement forecasting.

What is Country of Origin?

It describes the country(ies) where an article, brand, or design was manufactured, produced, designed, or branded.

What is Bill of Entry?

A bill of entry is a legal document that importers or customs agents file upon arrival of imported goods

How Batch group will help?

- Efficient Fulfillment: Sellers can fulfill the orders as per the promised details to the customer.

- Customs Compliant: Custom duty to be paid for inventory movement will be streamlined.

- Better Inventory Management: With lottables, it is easier to track inventory across warehouses

NOTE: Batching solution is currently applicable on SKU level traceability only in Enterprise Version.

Solution Details:

1. Feature Setup

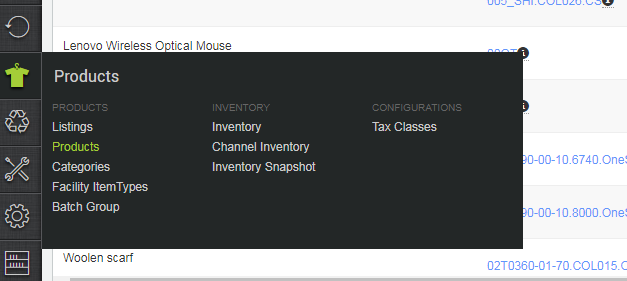

User goes to products page and defines batch groups. A batch group can be a unique code based on selected attributes i.e. MRP, Vendor Name, Cost, Mfg. Date, Expiry Date, Country of Origin, Bill of Entry and Vendor Batch Number.

2. GRN (through UI)

During GRN user can enter batch details for each incoming batch of that SKU and system will generate a unique batch code for each batch of that SKU. Same functionality can also be achieved using imports for bulk quantity.

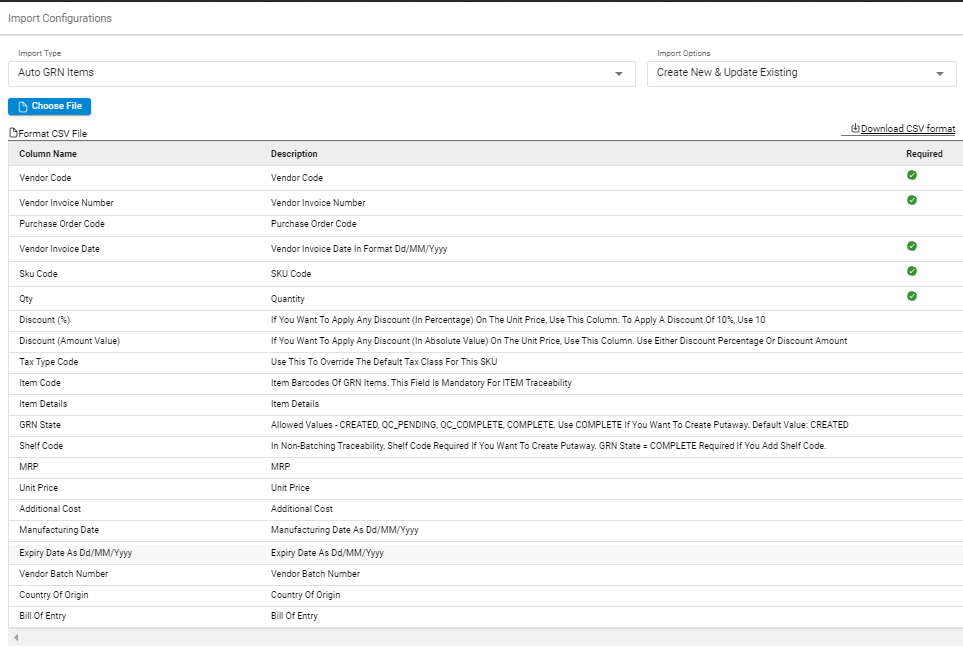

GRN (through Import)

3. Order Processing

For an incoming order system will allocate items from those SKU batches which have the nearest expiry date. User can also define no. of days for each SKU after which orders for that SKU will not be fulfillable. This will keep the warehouse inventory fresh at all times and avoids higher un-fulfilment rate.

Print batch/lot information on the invoice

The batch/lot information would now be saved at the invoice level, so that batch information can be easily utilized in invoice if required.

The batch wise details can be visible in the invoice tab of the order detail page.

Order Cancellation/Returns

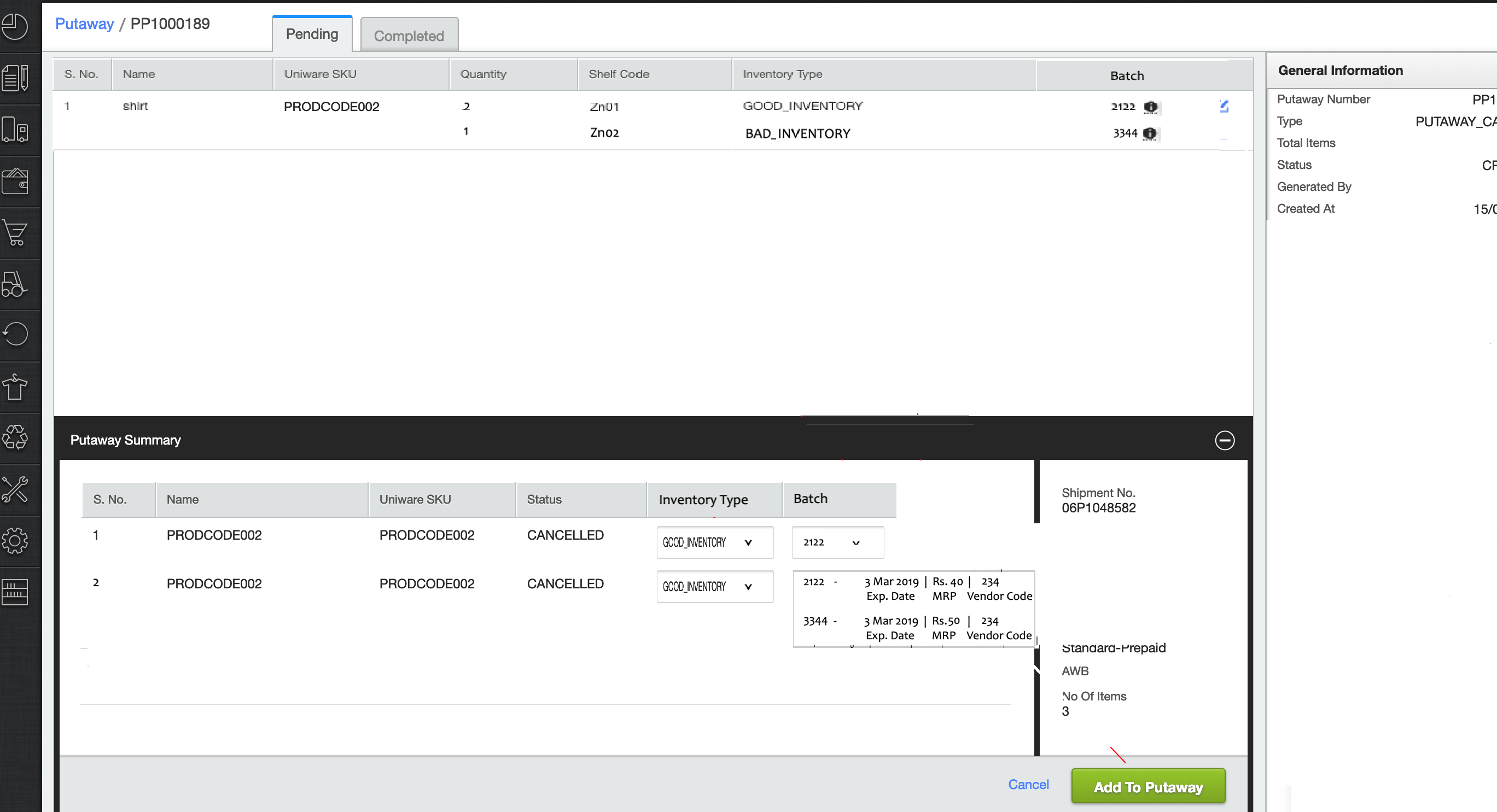

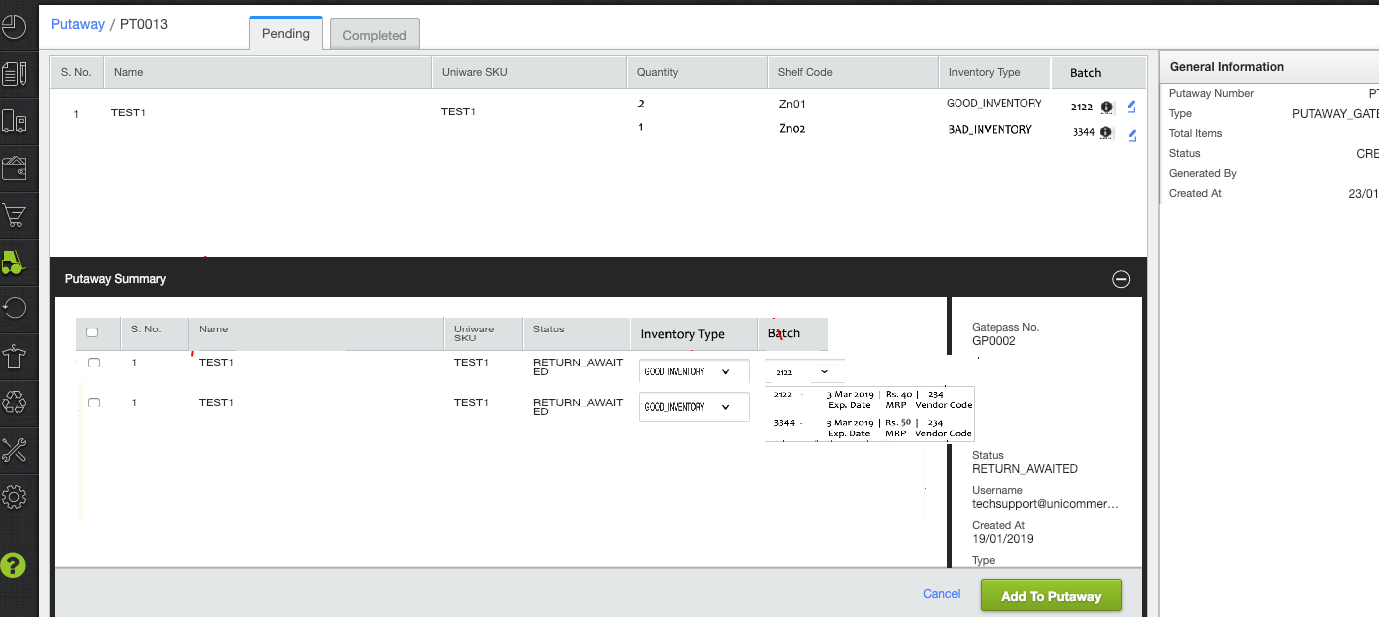

During cancellation, system will show all those batches from where the cancelled/returned items were picked during order fulfilment. User can select the relevant batch and system will suggest a shelf accordingly to place that item back in the warehouse.

Batch Selection at Invoicing Dock

Accurate batch and sale order item mapping during order fulfilment.

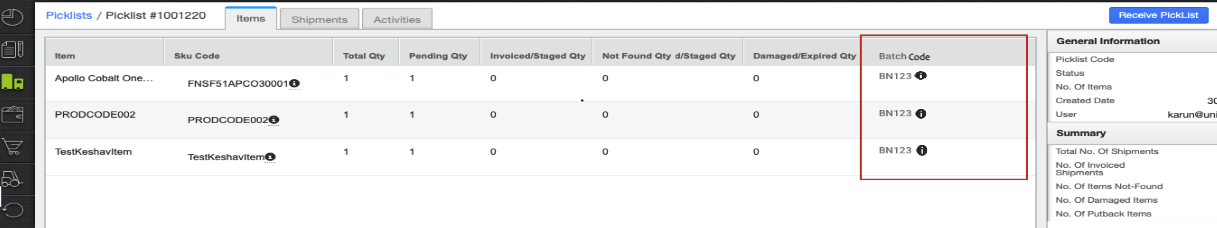

The sellers can now select batch/lot of the SKU while receiving picklist items at the invoicing dock. This would lead to increased accuracy.

4. Inventory Management

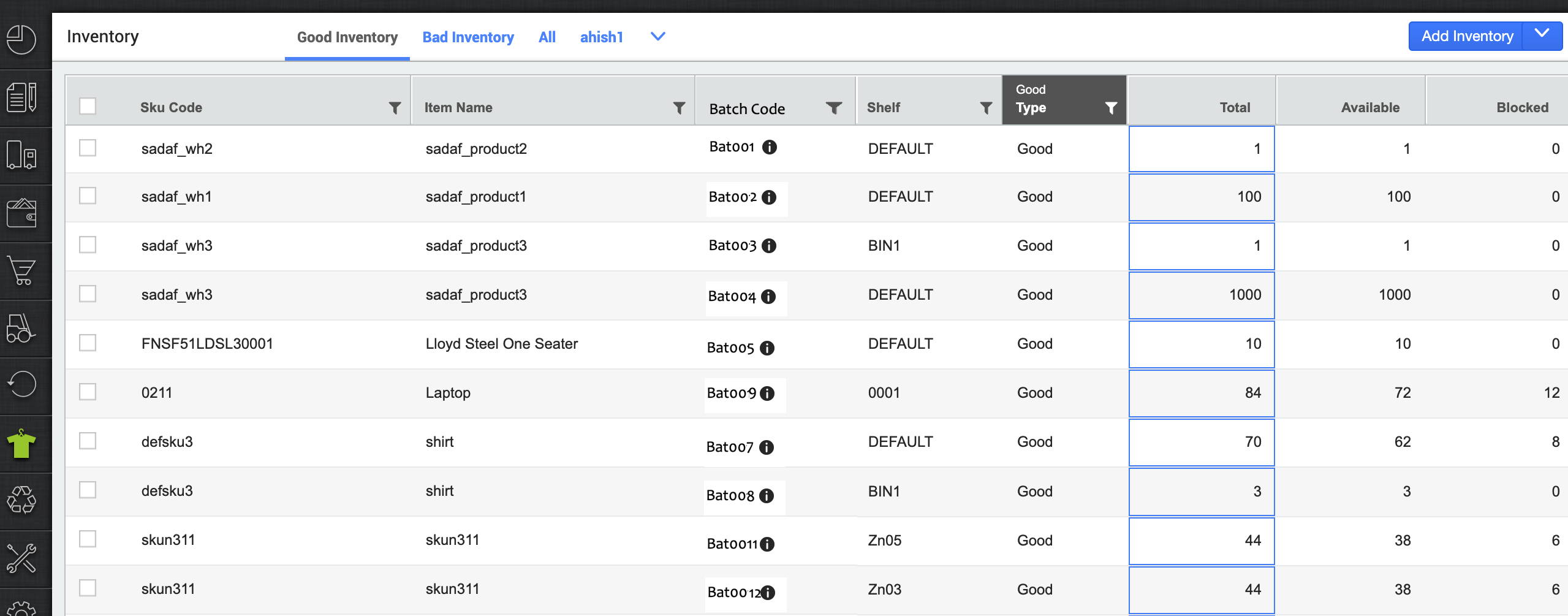

System will show a consolidated view of all SKUs, batchcodes, shelves and quantity on the inventory page. Multiple reports can be exported from the system that show batch details as well.

Shelf Transfer: User can do batch shelf transfer using inventory adjustment import utility

Inventory type adjustment: Marked good to bad inventory on Batching traceability. User can mark batches good/bad using inventory adjustment import utility. ‘Add Inventory’ option will be disabled for this feature as batched inventory can be added in the warehouse through GRN only.

5.Gatepass

Gatepass creation will be as usual. While inward items through stock_transfer or returnable gatepasses system will show the relevant batch details from where those items were picked during gatepass creation. User can select the relevant batch and the system will suggest a shelf accordingly.

6. Batch Reports

Uniware will provide standard reports which will contact all batch/shelf/SKU level details. Sellers can easily see all the unique batches of an SKU that have ever been created in the warehouse through a single export file.

Report Name- Batch details

Report Filters:

- SKU Code – Dropdown (Mandatory)

- Include Expired – Yes/No

- If Yes, then include expired inventory as well

- If No, then exclude expired inventory (expired!=1 in Batch table) [Default]

- Batch created between (Filter on created date in batch table)

- from date [default – beginning of the universe]

- to date [default – current date]

For further details & customization needs Click here and we will be happy to assist you. Also, you can connect with us using uniware Chat Support.

Note:-

- User raises PO for same/different SKU quantities using Uniware.

- During GRN, corresponding to the PO, user scans SKU codes and inward multiple batches of same/different SKUs

- During GRN, for each SKU batch user can enter Mfg. date, Expiry Date, MRP, Vendor batch number, cost etc.

- Uniware will suggest shelf to place incoming SKU batch. User can change the shelf code anytime before putaway completion.

- During order fulfilment, SKU batch with nearest expiry will be allocated first

- Uniware will enable returned order items to be kept into their respective batches/shelves.

- Uniware will provide reports to enable stock liquidation of expired batches, trace SKU batches back to vendors and prohibit sale of expired SKU batches

- Country Of Origin Lottable can identify the Batch Group.

- Bill Of Entry can be stored in Batch Group Parameter. Custom Field can be used to store other factors like Subjective QC reasons, etc.

- A seller can have different Bill of Entry for 2 batches. A Bill of Entry as per shipment.

- Same vendor can have 2 batches with different Country of Origin.